As an important component that combines the heating system with the mold structure,the shape design of the mold heating tube needs to highly match the geometric structure of the mold cavity.The ability to customize special-shaped bending has become a key influencing factor for the matching efficiency and heating uniformity of heating tubes.

Special-shaped bending mainly refers to the heating channels set up for non-standard molds,which achieve fixed-point heating and distributed control through specific geometric paths of heating tubes.Common bending forms include L-shaped,U-shaped,serpentine,ring-shaped,Z-shaped,double-layer loop,etc.,which are suitable for complex die cavity contours and space limitations.

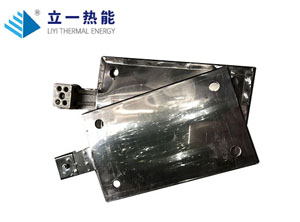

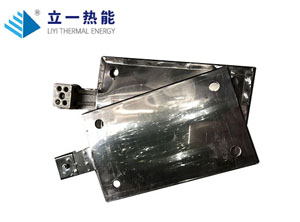

The heating tube is wrapped with high-temperature resistance wire and insulating medium in a stainless steel shell,featuring excellent plasticity and high-temperature resistance.The tube body is geometrically formed without affecting the integrity of the resistance wire through methods such as cold bending,hot bending,and positioning die bending.The bending radius,connection Angle and straight section length can be accurately controlled according to the drawings.

The customization process generally includes five major steps:electrothermal calculation,structural fitting,parameter confirmation,bending and forming,and positioning and welding.Some projects also require personalized designs such as thermocouple lead-out,junction box layout,and installation slot opening.

In high-precision molds such as multi-cavity injection molds,hot runner molds,and aluminum alloy die-casting molds,the special-shaped bending heating tubes can achieve uniform thermal field distribution,reducing forming defects and dimensional deviations.Some molds also require that the heating tubes be closely distributed along the cavity curve to enhance heat conduction efficiency.

Customized special-shaped bending is usually based on drawings and supports CAD data input and 3D space simulation.After customization is completed,the factory will provide the bending size diagram,physical positioning diagram and heating area description as a set,which is convenient for the customer to install quickly.

Irregular-shaped heating tubes have advantages such as dimensional flexibility,high thermal efficiency,and compact layout.They are suitable for use in medium and small batch mold production,high-precision plastic processing,die-casting thermal control systems,and other scenarios.